Southeastern Laboratories, Inc.

Serving the Water Treatment Industry Since 1973

Water Conservation

Because of a changing climate, reducing the environmental footprint of industrial operations has become more important than ever. It is no longer sufficient to simply attain sufficient profitability while avoiding discharge of toxic wastes. Increasingly industry must change strategies to become noticeably and substantially "greener", in both the use of raw materials like water, and in the discharge of by-products heretofore considered benign (such as carbon, heat, odor, sludge, and mildly saline water). This is leading companies to be more efficient in using resources, handling waste, optimizing supply chain operations and producing more environmentally friendly products. As water becomes more of a scarce resource, corporations are developing sustainability policies based on an effective water strategy. This strategy should encompass the full spectrum of water and wastewater treatments to uncover opportunities for cost savings, reduced downtime and improved operations. Site managers, corporate officers, engineering firms and water saving advocates should develop a water efficiency objective and meet this objective by applying a variety of tools and metrics. What gets measured gets managed.

Role of ProMoss™

ProMoss™ has a unique ability to act as a natural water softener, removing impurities from water such as calcium, magnesium, iron and other metals that can result in scaling and corrosion problems in water systems. ProMoss™ is made from the leaves of a particular species of Sphagnum moss. It is rich in carboxylic acid groups that give ProMoss™ its high cation exchange capacity. Hydrogen ions are released in the exchange process effectively neutralizing alkalinity.

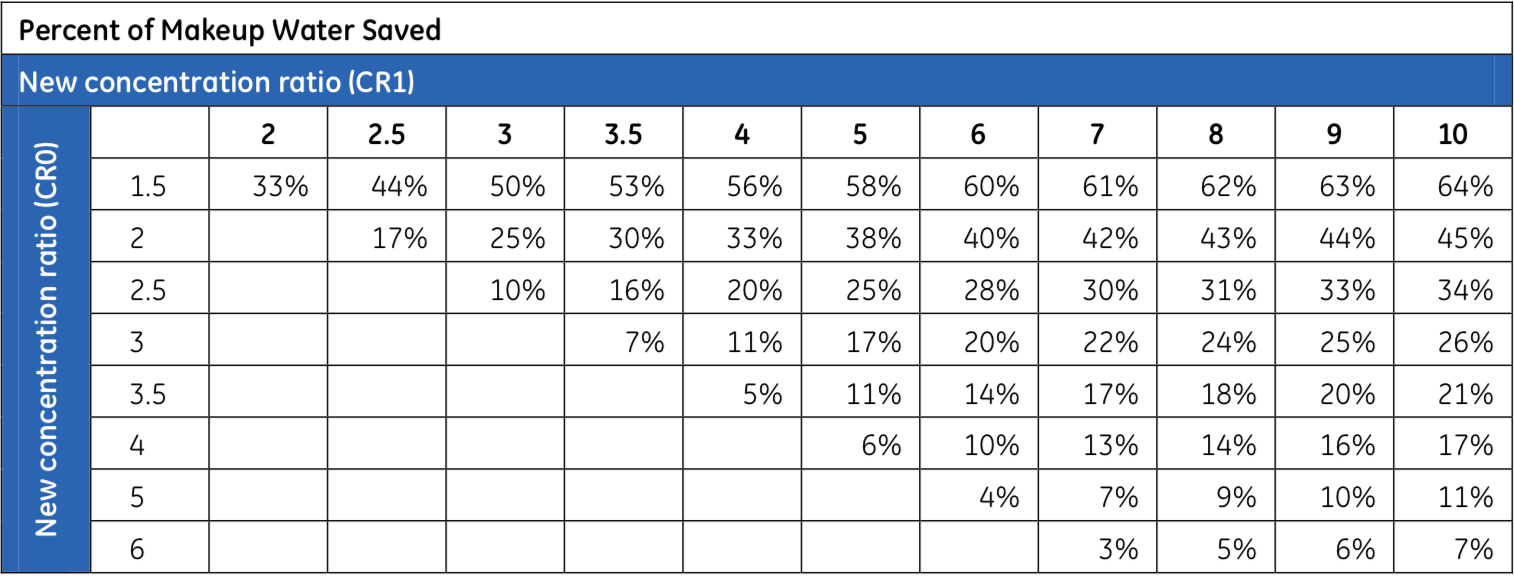

So what does this mean to end users applying this program in their evaporative cooling water systems? Removing cations that limit cycling in evaporative systems translates to water conservation. ProMoss™ lowers the scaling potential of the water by lowering hardness and alkalinity levels, thereby allowing water to be "cycled" higher in cooling towers beore scaling conditions occur.

For many facilities, cooling towers represent the single largest opportunity for greater water efficiency. Cooling towers should be investigated to determine how many times water circulates before it is bled off and discharged. Increasing the recycle rate of the tower results in multiple savings, from water and sewer costs to savings on treatment costs. Typically, cooling towers consume a significant portion of total waste in a facility.